Pulley Lagging

Posted on Wednesday Nov 06, 2019 at 09:09PM in Belting & Conveyors

Article By: Billy Witherspoon

Strategic Business Manager

One of the most often overlooked/neglected components of a conveyor system is Pulley Lagging.

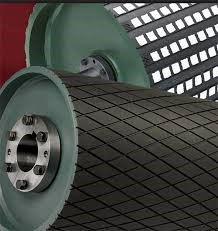

Pulley lagging is a covered/coating over the surface of either a driven or non-driven pulley used as a wear surface and/or friction layer. Typical conveyor pulleys are made of a steel outer shell with end discs welded in each end to allow for mounting to a conveyor shaft, with numerous choices on mounting options. Lagging is added to the steel outer shell of the pulley, providing a replaceable wearing surface for non-drive pulleys. For driven pulleys lagging is typically made to increase the friction between the pulley and the belt being driven, with the added benefit of being a replaceable surface. Lagging comes in many rubber and non-rubber compounds, multiple surface patterns for varied applications and needs to be chosen based on the application for best results.

Increasing the friction at the drive pulley allows your conveyor to run at less overall tension, increasing belt life, as well as, bearing and component life. Proper lagging can eliminate belt slippage in wet and frigid conditions preventing “Burn Throughs” (Pulley spinning due to loss of friction will burn through the bottom of the belt).

Pulley Lagging can be purchased already applied to a new pulley direct form the manufacturer or there are numerous aftermarket options. We stock and can provide installation on multiple aftermarket lagging products. High Tensile strength rubber with Diamond pattern or Flat surface can be bonded to your existing pulley either in our shop or on your conveyor. In areas where you need more friction we can provide Rubber lagging with Ceramic inserts that provide more friction and wear resistance. Weld-on “Slide Lag” is also available. Whatever your application requires, we have you and your pulley Covered!