CHOOSING BETWEEN BALL BEARING & TAPERED ROLLER BEARING CONVEYOR IDLERS

Posted on Tuesday Dec 04, 2018 at 09:38PM in Belting & Conveyors

Article By: Dave Corson, Business Development Manager, IMSCO - Mining Division

In today’s increasing demands put on belt conveyors to transport material from point A to point B, the proper selection of the components used on your belt conveyors becomes even more critical. This includes, but is not limited to higher tonnage demands, wider belts to meet these demands, and the ever increasing belt speeds (FPM) that must be achieved for these increasing tonnages.

Over my 30+ years of experience working around these conveyors in the mining industry, I have had multiple discussions with mine managers, engineers, maintenance superintendants, etc. regarding the “myths” and “truths” around selecting conveyor idlers for their projects. There are a number of “quality” manufacturers in the USA, some of which manufacture BOTH, tapered roller and ball bearing idlers.

Let’s look at some of the “myths” surrounding the ball bearing -vs- tapered roller bearing controversy.

- Ball Bearing idlers have lower rotational resistance.

- This is FALSE. The rotational resistance of the conveyor idler roll, depends on the grease and seal arrangement of the idler. NOT the bearing.

- Tapered Roller bearings MUST BE REGREASED.

- This is FALSE. Although regreasing any bearing is always recommended to extend the life of the bearing and equipment, “Sealed for Life” tapered roller bearing idlers have been manufactured in the USA for over 40 years, and have proven themselves in the most demanding mining applications.

- Tapered Roller bearings MUST BE PRELOADED.

- This is FALSE. Quality manufacturers of TRB idlers, assemble their roll heads with strictly controlled, proprietary end play tolerances. NOT PRELOADED!

- Tapered Roller bearing idlers allow only 3 minutes of angular misalignment.

- This is FALSE. Quality manufacturers of TRB conveyor idlers, use “Modified Geometry” tapered roller bearings, and are tested to withstand up to 16 minutes of angular deflection.

We offer our customers many options when “selecting” the BEST “solution” for maximizing the life and efficiencies of the components on their belt conveyors. Choosing the right component for their application, is key to providing long term solutions for them.

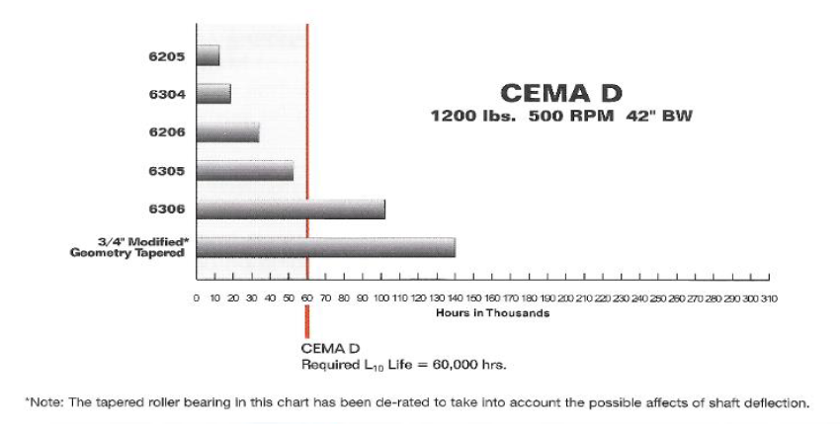

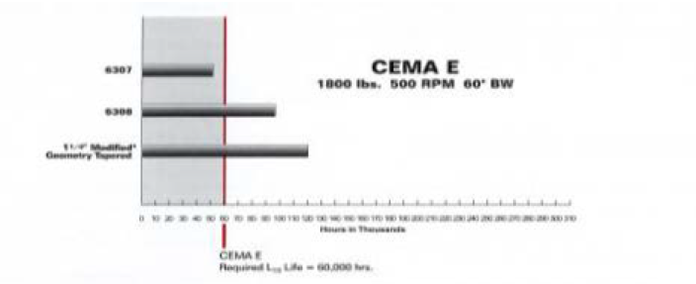

In upcoming discussions, we will look at the different bearings and calculated L10 life associated with the different bearings used today in conveyor idlers.